Tubing Installation Guide

Step 1: Clean the Panels

Clearing the panels and tubing channels of debris will ensure the tubing sits flush and level. This is essential to a well functioning radiant system.

- Use a broom, shop vacuum or leaf blower to clear the debris from the panel and tubing channels

- Use a 1/2″ conduit to break loose stuck-on material

Step 2: Mark the Tubing Paths

- Follow the Tubing Layout plan set and mark the tubing paths on your panels with a permanent marker

- Clearly mark turns, bury points, custom routes, and manifold locations

- Mark locations of all plumbing waste lines

- Mark each loop to avoid any future confusion

- Use a Sharpie or wax pencil to mark panels.

- Use a 3/4″ drill bit to create a 3/4″ x 11/2″ bury point which will help prevent the tube from kinking.

Step 3: Return Lines to Manifolds

To return the PEX tubing back to the manifolds, there are a few different options which will work.

- Method 1

Use the existing channels in the panels to return the tubing to the manifold - Method 2

Create custom routes in the panel and return the tubing back to the manifold - Method 3

Create a bury point and feed the tubing back to the manifold by going through the subfloor (illustration) - Method 4

Use the “panel cut back” to create a tubing channel above the slab for the tubing to return to the manifold. Fill with Portland cement to create a level surface (illustration)

Step 4: Custom Routes

Follow the instructions for Custom Routes

Step 5: Install Tubing

- Avoid installing tubing at temperatures below 50˚F as the tubing becomes rigid and difficult to bend

- ONLY use tubing from our Approved Tubing List

- Use a 16oz. rubber mallet to secure the tubing in the channel (be sure the tubing sits level and flush with the top of the panel)

- DO NOT use silicone/adhesive in the channels

- Tape over the ends of the tubing to prevent debris from clogging the lines

- A tubing uncoiler will help avoid twists and kinks when installing the tubing. It is an excellent investment and highly recommended for large jobs

- Use nail plates to secure tubing as needed and remove before finish floors are installed

Step 6: Install Manifold(s)

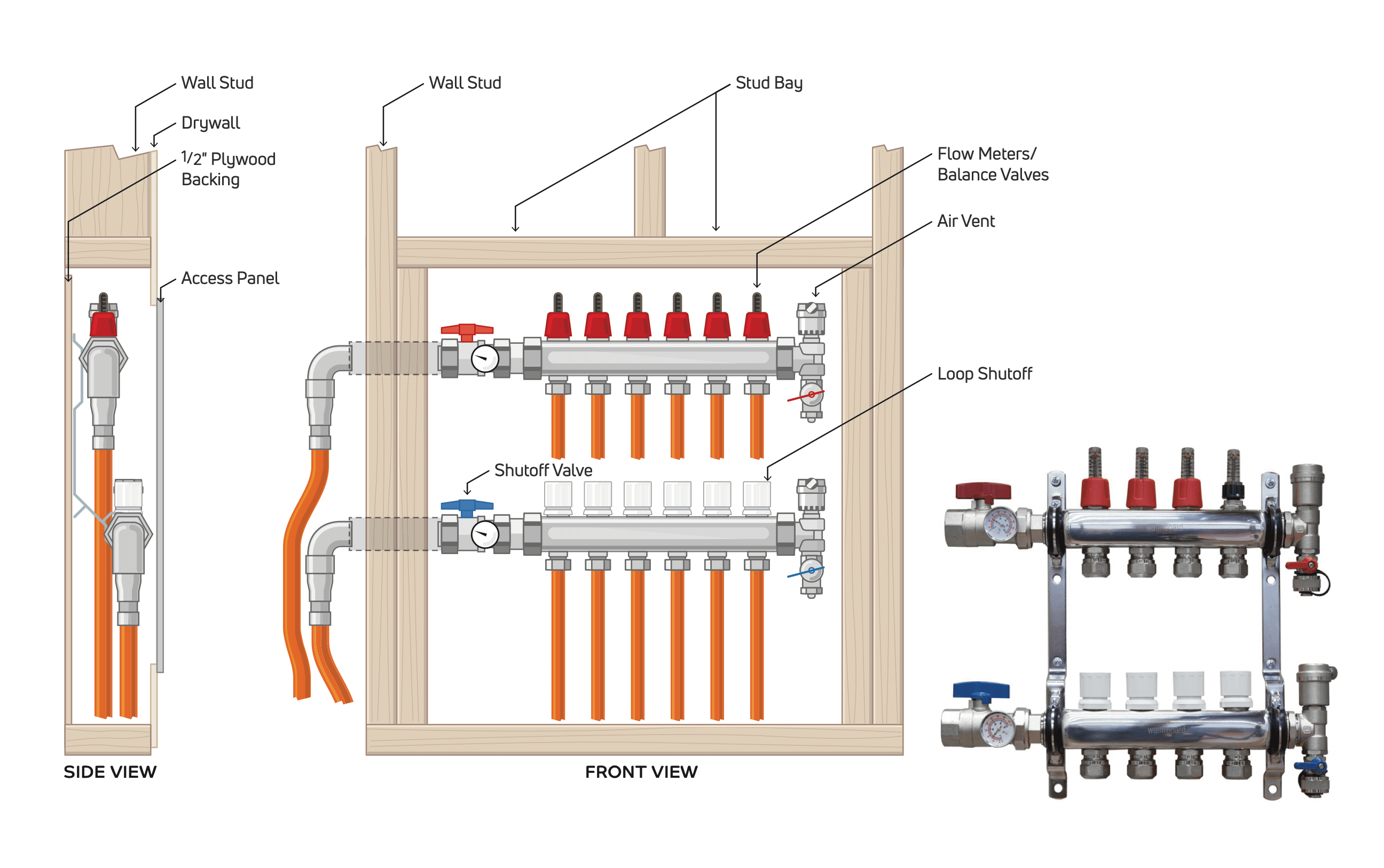

- Follow all installation details and specifications documented by the manufacturer. Manifolds are usually placed in closets or between interior wall stud bays with an access door

- Clearly mark all supply and return loops. Document rooms and zones on the manifolds to avoid future confusion

- Pressure test all loops to the mechanical code requirement of 100 PSI for 15 minutes. After this, the PSI will drop 5-10% (this is normal)

- After the 15 minutes, lower the air pressure to 60 PSI and maintain during the construction process.

- After this, the PSI will drop 5-10% (this is normal)

See Manifold Install guide.

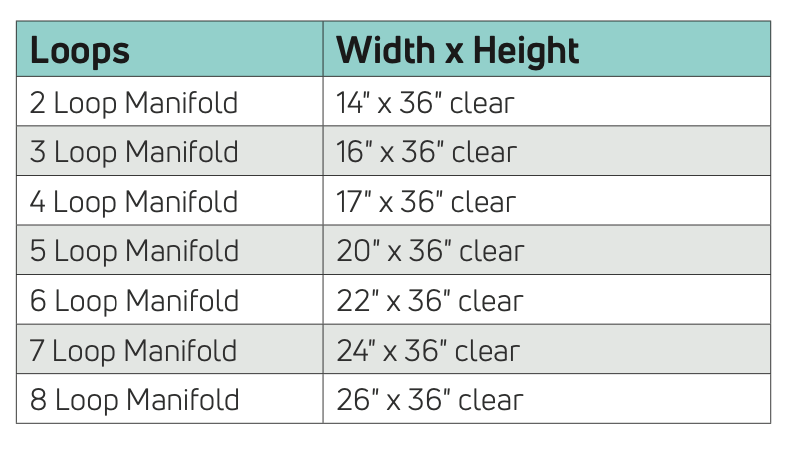

Minimum Framing Dimensions:

Step 7: Tubing Repair

Every tubing manufacturer makes a repair coupler to repair a punctured section of tubing.

Repairing tubing damage is an easy fix and should require less than 30 minutes to complete.

- Pop the tube out of the tubing channel

- Cut out the damaged area and insert the coupler

- Chisel a groove into the panel to accommodate the size of the coupler

Other recommendations:

- The tubing MUST be level and flush with the surface of Warmboard.

- Consider Ram Board (or equivalent) to help protect the tubing in high traffic areas.

Next, follow this guide for Custom Routing and manifold installation.

Tubing Repair

Tubing Repair instructions

Should damage occur, Warmboard offers two types of repair couplers.

All repairs MUST are done by a licensed plumber or radiant contractor.

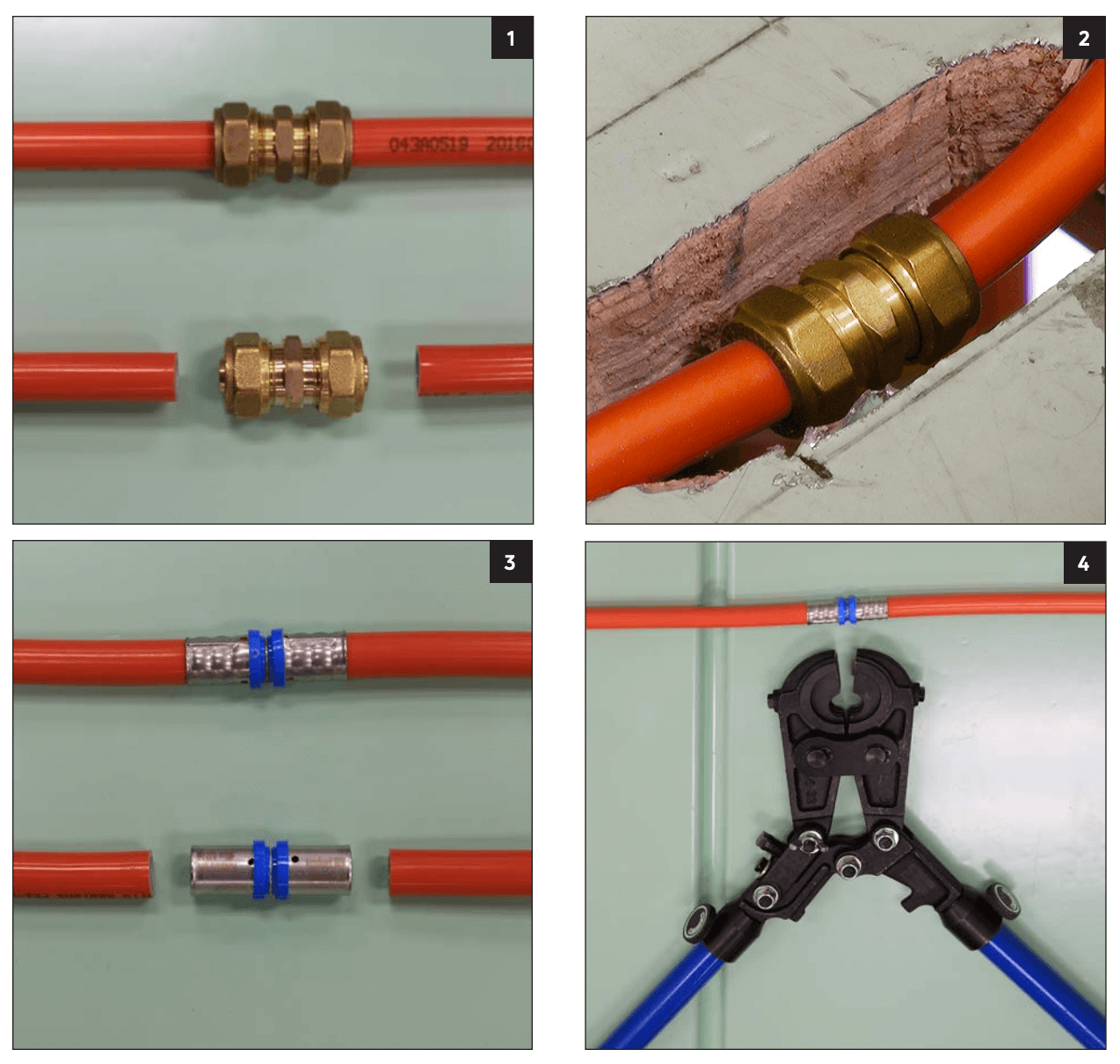

Method 1: Threaded

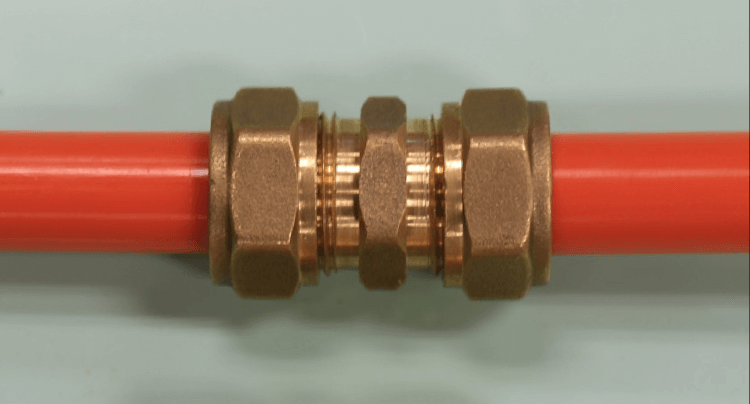

This fitting has an outside dimension of 1″ and uses two brass compression fittings and a brass nipple to create a repair (photo 1)

- Chisel out part of the Warmboard tubing channel to accommodate the fitting (photo 2)

- Cut the tubing square and use the chamfering tool before installing fittings. DO NOT use tape or dope on the threads

Method 2: Pressed

This stainless/brass repair coupling (photo 3) uses a permanent compression and requires the purchase of a Warmboard-supplied pressing tool (photo 4). This fitting has an outside dimension of 13 /16″.

- Chisel out part of the Warmboard tubing channel to accommodate the fitting

- Cut the tubing square and use the chamfering tool before installing fittings. DO NOT use tape or dope on the threads

Manifold cabinet diagram